ERP Connector

Shipbuilding is a complex manufacturing endeavor where many processes and events occur simultaneously. Ships are often still being designed while they are under construction. As a result, it is very important that design and construction activities are closely synchronized, particularly to insure that last minute design changes are transmitted to production.

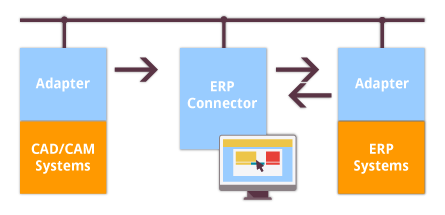

Unreported design changes can lead to extensive rework with resulting cost and schedule overruns. The Topgallant® ERP Connector solution avoids these problems by integrating and distributing design and production information quickly and effectively between CAD and ERP Systems.

Topgallant® ERP Connector transfers data from a design system to a manufacturing system, integrating the information and providing the user with a complete overview. ERP Connector monitors data files from the CAD (or nesting) system and determines whether there is an initial transfer or a significant design change requiring processing. For new changes, ERP Connector creates the production-relevant data sets to be transferred into the ERP system.

ERP Connector offers several important advantages:

- Provides a system overview from design to production

- Automates analysis and identification of design changes

- Connects to multiple CAD/CAM systems and includes browser application

- Supports parallel processes for multiple projects

- Is platform independent